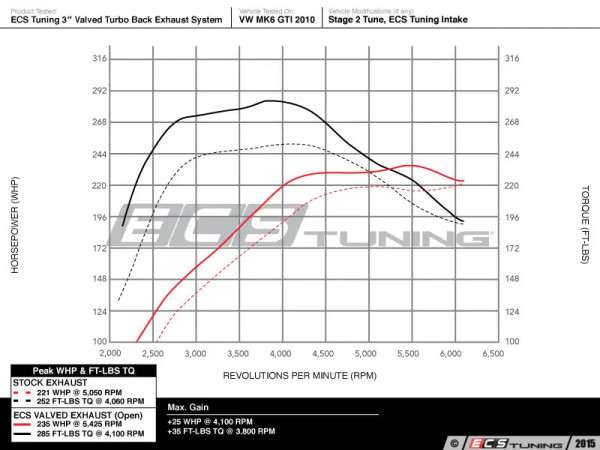

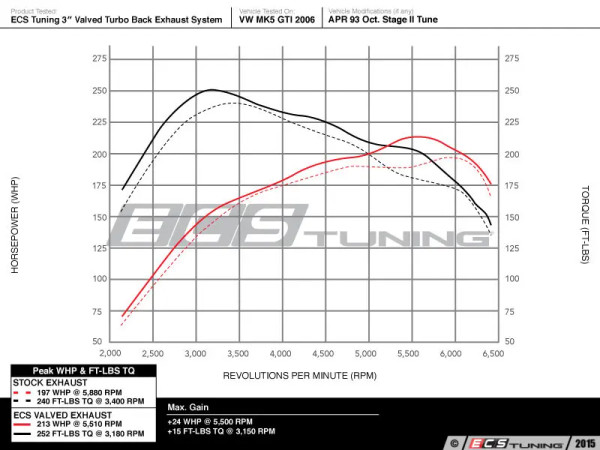

The perfect way to unleash hidden horsepower in a modern turbocharged engine is to upgrade the restrictive factory downpipe with a smoother, higher flowing unit. This is a great way to increase performance and add a sophisticated growl to the exhaust note. Ideal performance is achieved through expelling exhaust gasses at maximum velocity through a larger diameter, freer flowing downpipe due to smoother bend radius, larger internal diameter and a less-restrictive catalytic converter. We measured maximum gains of +25WHP and +35ft/lbs of torque on our ECS MK6 GTI when equipped with APR Stage 2 ECU software, ECS Luft-Technik Intake System and ECS Valved Catback Exhaust System.

When paired with our standards of quality and design requirements here at ECS Tuning, we can humbly provide to you the greatest downpipe upgrade system available. Through multiple design iterations and stringent product testing, we have engineered our High Flow Downpipe to not only free up horsepower, but to provide trouble-free installation with a true and honest, perfect fitment guarantee.

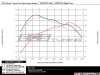

Designed and engineered in house, our High Flow Downpipe System utilizes only premium materials and world-class manufacturing techniques to deliver unmatched quality and reliability. Starting at the turbine housing our mating flange is made from 3/8" thick CNC-Cut T304 stainless steel and is then precision ground for an optimum gasket sealing surface. A new downpipe gasket and copper flanged nuts are included for a trouble free install.

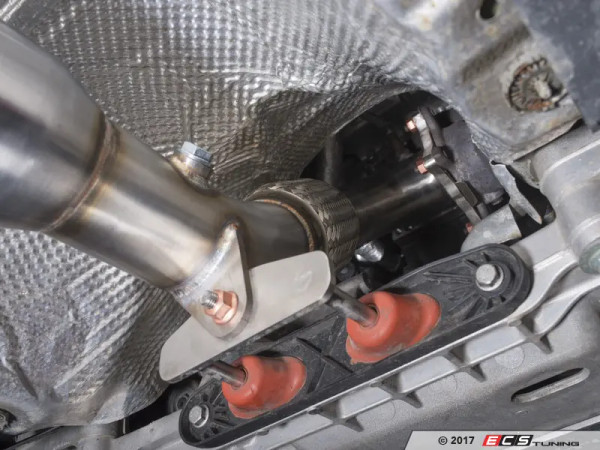

All exhaust tubing is 3.0" T304 Stainless Steel CNC Mandrel Bent with .065" wall thickness for reduced cabin noise and increased life span of the product. Each weld joint is hand TIG welded for precision and strength and eye-catching beauty. In addition, our downpipe weighs 4 lbs less than the OEM downpipe assembly.

A stainless steel flex section connects the downpipe to the 200 cell high flow metallic catalytic converter and provides proper range of motion and heat expansion. The downpipe bolts to our CNC-cut stainless downpipe bracket which features barbed hanger connections to the OEM downpipe mounting bushings to prevent disconnection. A stainless M10 bolt, washer and copper flanged nut are included to bolt the assembly together.

Stainless steel oxygen sensor bungs are TIG welded in OE-locations so no extension harness are needed. A third oxygen sensor bung is welded on for specific CBFA fitment. CCTA (and FSI) engines will use the included zinc plated oxygen sensor bung plug with sealing washer to plug this port off.

To complete our downpipe system we've included a 3.0" expanded reducer with 3.0" Accu-Seal exhaust clamp that reduces to the OEM exhaust size along with a zinc coated clamping sleeve for OEM catback fitment. Please note that our midpipe ends at the factory clamping location and is 3.0" OD at this connection point. If using an aftermarket catback system some modifications or additional components may be needed.

Our ECS Tuning High Flow Downpipe System offers impressive real world results. Each system is hand crafted from premium materials and comes with a 5 year limited warranty with a perfect fitment guarantee! This means less frustration and less downtime during installation over many others.

Get yours today and experience the difference!

NOTE: Aftermarket ECU software is required to keep MIL (Malfunction Indicator Lamp) off and is recommended to maximize performance gains as advertised.